Lycoming IO-320 Parts Manual: A Comprehensive Overview

This manual, PC-303, details parts for Lycoming IO-320, AIO-320, LIO-320, and AEIO-320 engines․

It covers overhaul parts, cylinder assemblies, and various model variations like -B1A, -E2A, and more․

Superior Millennium kits (SL36006W-A20P) and narrow/wide deck flange specifics are also included within this catalog․

The Lycoming IO-320 is a renowned four-cylinder, normally aspirated aircraft engine celebrated for its reliability and performance․ This engine, and its variants like the AIO-320 and LIO-320, have powered a multitude of general aviation aircraft for decades, becoming a staple in the industry․ Understanding the intricacies of its components is crucial for pilots, mechanics, and aviation enthusiasts alike․

This engine’s longevity stems from continuous improvements over six decades, resulting in a robust and well-documented design․ The availability of comprehensive parts manuals, such as PC-303, is paramount for maintaining these engines to the highest standards․ These manuals detail everything from cylinder assemblies to crankshaft specifications, ensuring accurate identification and replacement of parts․

The IO-320’s popularity also means a readily available supply of replacement parts and overhaul kits, like the Superior Millennium Cylinder Power Assembly Kit (SL36006W-A20P)․ Proper maintenance, guided by detailed documentation, is key to maximizing the engine’s lifespan and ensuring safe operation․ This introduction sets the stage for a deeper dive into the specific components and systems of the Lycoming IO-320․

Scope of the Parts Manual

This Lycoming IO-320 parts manual, primarily PC-303, serves as a definitive guide for identifying and procuring components for the IO-320, AIO-320, LIO-320, and AEIO-320 engine series․ It encompasses a detailed breakdown of all major engine systems, including cylinder assemblies, pistons, connecting rods, the crankshaft, and valve train components․

The manual’s scope extends to critical systems like the carburetor, fuel system, ignition, and oil cooling systems․ It provides specific part numbers, detailed illustrations, and specifications for each component, facilitating accurate ordering and installation․ Furthermore, it covers various model variations, such as the -B1A, -E2A, and others, ensuring compatibility․

This catalog also includes information on overhaul parts replacement lists, like those offered by Lycoming, and details regarding cylinder flange types – narrow and wide deck configurations․ It’s an invaluable resource for mechanics performing routine maintenance, overhauls, or repairs, ensuring adherence to manufacturer specifications and maintaining airworthiness․

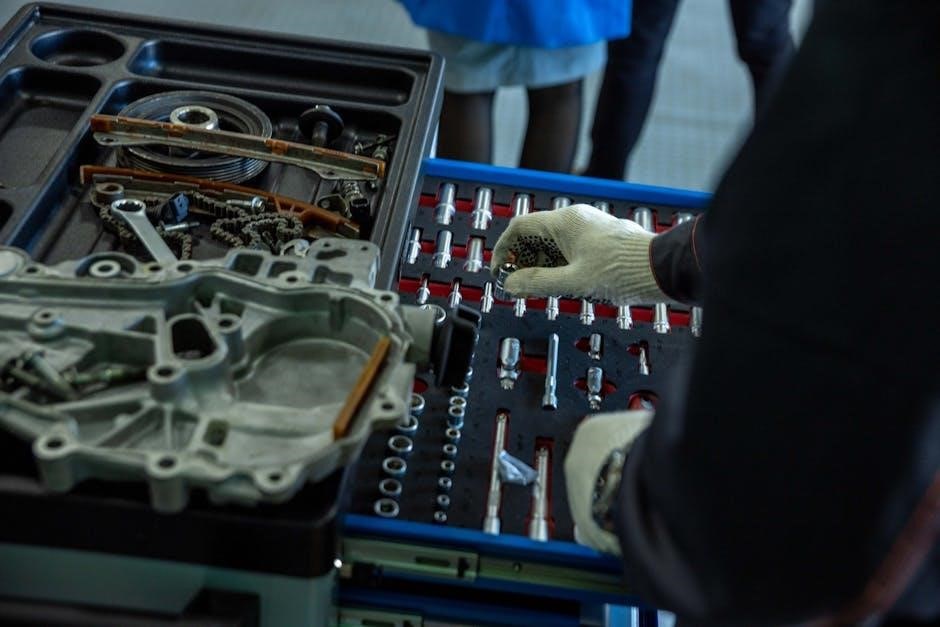

Engine Components & Systems

The IO-320 engine comprises vital systems: cylinders, pistons, crankshaft, camshaft, fuel, ignition, and oil cooling․

Detailed parts breakdowns are available for each system, ensuring proper maintenance and repair procedures․

Cylinder Assemblies

Cylinder assemblies are critical components of the Lycoming IO-320 engine, directly impacting performance and reliability․ These assemblies include the cylinder barrel, cylinder head, valves, and related hardware․ The parts manual, PC-303, provides detailed breakdowns of each component within the cylinder assembly, specifying part numbers and material specifications․

Superior Millennium Cylinder Power Assembly Kits, such as SL36006W-A20P, offer comprehensive replacement options for worn or damaged cylinders․ The manual differentiates between narrow deck and wide deck cylinder flanges, crucial for compatibility with specific engine models (IO-320-B1A, -E2A, etc․)․

Understanding the nuances of cylinder flange types is essential during overhaul․ The catalog details various cylinder configurations and their corresponding parts lists, facilitating accurate identification and ordering of replacement components․ Proper cylinder assembly ensures optimal compression and combustion, contributing to efficient engine operation․

Piston and Connecting Rod Assemblies

The Lycoming IO-320’s piston and connecting rod assemblies translate combustion force into rotational power․ The parts manual, PC-303, meticulously details each component – pistons, connecting rods, piston pins, and retainers – with precise part numbers and specifications․ Accurate replacement is vital for maintaining engine balance and minimizing vibration․

Detailed information regarding piston pin and retainer specifications is included, ensuring proper fit and securement․ Connecting rod bearing specifications are also outlined, crucial for preventing premature wear and maintaining oil pressure․ The manual assists in identifying the correct bearings based on engine model and operating conditions․

During overhaul, careful inspection and potential replacement of these assemblies are paramount․ The catalog facilitates sourcing certified Lycoming parts, guaranteeing quality and reliability for optimal engine performance and longevity․

Crankcase and Accessory Case

The Lycoming IO-320 crankcase forms the structural foundation of the engine, housing the crankshaft and providing mounting points for accessories․ PC-303’s parts manual provides a comprehensive breakdown of the crankcase and accessory case components, including detailed diagrams and part numbers for various model iterations․

Specific attention is given to narrow deck versus wide deck cylinder flanges, a critical distinction during overhaul․ Certified Lycoming O-320 narrow deck E2A spot-faced flange crankcases are frequently available, and the manual aids in verifying compatibility․ The catalog details all necessary gaskets, seals, and mounting hardware․

Proper inspection for cracks or damage is essential during maintenance․ The manual supports accurate identification of replacement parts, ensuring a secure and reliable engine structure for sustained performance and operational safety․

Camshaft and Valve Train

The Lycoming IO-320 camshaft and valve train are critical for precise valve timing and efficient engine operation․ The PC-303 parts manual meticulously details each component, from the camshaft itself to lifters, pushrods, rocker arms, and valve springs․

Detailed illustrations and part numbers facilitate accurate identification and replacement during overhaul or maintenance․ The manual assists in selecting the correct valve and guide details, ensuring proper sealing and minimizing wear․ It’s crucial to inspect these components for wear or damage, as they directly impact engine performance․

Proper valve train assembly, guided by the manual, is essential for optimal engine power and longevity․ The catalog supports technicians in maintaining the precise tolerances required for reliable operation․

Carburetor and Fuel System

The Lycoming IO-320 fuel system, while often utilizing fuel injection in the IO-series, relies on precise components detailed within the PC-303 parts manual․ This section covers fuel pumps, lines, filters, and associated hardware necessary for delivering a consistent fuel supply to the engine․

Although the IO-320 is fuel-injected, understanding the broader fuel system components is vital for comprehensive maintenance; The manual provides exploded views and part numbers for each element, aiding in accurate identification and ordering of replacement parts․

Proper fuel system maintenance, guided by the catalog, ensures optimal engine performance and prevents potential issues like fuel starvation or contamination․ Technicians can rely on this resource for detailed specifications and assembly instructions․

Ignition System Components

The Lycoming IO-320 ignition system, crucial for reliable engine starting and operation, is thoroughly documented in the PC-303 parts manual․ This section details magnetos, ignition wiring harnesses, spark plugs, and associated components essential for generating the high-voltage spark needed for combustion․

The manual provides detailed diagrams illustrating the correct routing of ignition wires and the proper installation of magneto components․ Precise part numbers are listed for each item, facilitating accurate replacement during maintenance or overhaul procedures․

Maintaining a properly functioning ignition system, guided by the catalog, is paramount for engine safety and performance․ Technicians can utilize this resource to diagnose issues and ensure the system meets Lycoming’s stringent specifications․

Oil System Components

The Lycoming IO-320 engine’s oil system, vital for lubrication and cooling, is comprehensively covered within the PC-303 parts manual․ This section details the oil pump, pressure relief valve, oil filter, oil cooler, and all associated lines and fittings necessary for maintaining optimal engine health․

Detailed exploded views illustrate the assembly and disassembly of the oil pump, alongside precise specifications for bearing clearances and pressure settings․ The manual lists part numbers for replacement seals, gaskets, and other consumable items, ensuring accurate repairs․

Proper oil system maintenance, guided by the catalog, is critical for preventing engine wear and maximizing its lifespan․ Technicians can rely on this resource for accurate component identification and correct installation procedures․

Cooling System Components

The Lycoming IO-320 engine’s cooling system, essential for temperature regulation, receives detailed attention within the PC-303 parts manual․ This section meticulously outlines components like the oil cooler, coolant hoses, ducting, and baffling assemblies crucial for efficient heat dissipation․

Exploded diagrams showcase the precise arrangement of each component, facilitating accurate assembly and repair․ The manual provides specific part numbers for replacement hoses, clamps, and mounting hardware, ensuring compatibility and reliability․

Maintaining a properly functioning cooling system is paramount for preventing engine overheating and potential damage․ Technicians can utilize this catalog to identify worn or damaged parts and perform effective repairs, extending the engine’s operational life and ensuring safe flight operations․

Detailed Parts Breakdown

This section provides granular detail on individual components,

including cylinder heads, pistons, crankshafts, and oil pumps․

Part numbers, specifications, and diagrams aid precise identification and repair․

Cylinder Head Parts

The cylinder head is a critical component, and this breakdown details its numerous parts․ This includes valves – both intake and exhaust – along with their corresponding guides, springs, and retainers․ Detailed specifications for each valve are provided, ensuring correct replacement for optimal engine performance․ Further, the catalog outlines the components of the valve seats, crucial for maintaining compression․

Information on rocker arms, pushrods, and rocker arm studs is also included, alongside details regarding the cylinder head bolts and gaskets necessary for proper sealing․ The catalog specifies materials and dimensions for each part, aiding in accurate identification and sourcing․ Diagrams illustrate the assembly of the cylinder head, clarifying the relationship between components․ This section is vital for any overhaul or repair involving the cylinder head assembly of the Lycoming IO-320 engine;

Valve and Guide Details

This section provides granular detail regarding the valves and guides within the Lycoming IO-320 engine․ It meticulously lists specifications for both intake and exhaust valves, including dimensions, materials, and acceptable wear limits․ Valve guide specifications are equally detailed, covering inner diameter, outer diameter, and material composition․

The catalog clarifies the proper installation procedures for valve guides, emphasizing the importance of correct alignment and interference fit․ Information on valve stem seals is also included, detailing their function in preventing oil leakage into the combustion chamber․ Diagrams illustrate the valve and guide assembly, showcasing the relationship between components․ This detailed breakdown ensures technicians can accurately identify, inspect, and replace valves and guides, maintaining optimal engine performance and compression․ Proper valve and guide maintenance is crucial for engine longevity․

Piston Pin and Retainer Information

This section of the Lycoming IO-320 parts manual focuses on the critical components connecting the piston to the connecting rod: the piston pin and its retainers․ Detailed specifications are provided for piston pin diameter, length, and material composition, ensuring correct component matching․ The catalog outlines various retainer types – including circlips and spanner locks – with precise dimensions and installation instructions․

Emphasis is placed on proper pin-to-bore clearance, highlighting the importance of accurate measurement and potential wear considerations; Diagrams illustrate the correct orientation of retainers and the proper method for pin installation and removal․ This section also details acceptable wear limits for both the piston pin and its bore, guiding technicians in determining component serviceability․ Maintaining these components is vital for preventing catastrophic engine failure․

Connecting Rod Bearing Specifications

The Lycoming IO-320 parts manual dedicates a crucial section to connecting rod bearing specifications, detailing dimensions, materials, and clearances essential for proper engine function․ This includes precise information on bearing shell inner diameter, width, and radial clearance, alongside acceptable wear limits․ The catalog specifies different bearing materials – typically tri-metal or polymer-coated – and their corresponding applications within the IO-320 series․

Detailed charts illustrate the relationship between bearing size, crankshaft journal diameter, and required shims to achieve optimal clearance․ Proper installation procedures, including lubrication guidelines and torque values, are also outlined․ Technicians rely on this information to ensure smooth operation, minimize friction, and prevent bearing failure, a common cause of engine damage․ Accurate adherence to these specifications is paramount for engine longevity․

Crankshaft and Main Bearing Details

The Lycoming IO-320 parts manual provides extensive details regarding the crankshaft and its associated main bearings, crucial components for engine stability and power transmission․ Specifications cover crankshaft journal diameters, counterweight dimensions, and material composition, alongside detailed diagrams illustrating component relationships․ The manual meticulously outlines acceptable wear limits for crankshaft journals and specifies procedures for inspection and refurbishment․

Main bearing details include shell dimensions, material types (typically tri-metal), and clearance specifications․ Charts correlate bearing sizes to crankshaft journal diameters, guiding technicians in selecting the appropriate bearings for optimal performance․ Torque values for main bearing cap bolts are precisely defined, ensuring proper clamping force․ This section emphasizes the importance of accurate assembly and adherence to Lycoming’s standards to prevent catastrophic engine failure․

Oil Pump and Pressure Relief Valve

The Lycoming IO-320 parts manual dedicates a significant section to the oil pump and pressure relief valve, vital for maintaining consistent lubrication throughout the engine․ Detailed exploded views illustrate the pump’s internal components – gears, housing, and scavenge ports – alongside precise measurements and material specifications․ The manual outlines procedures for inspecting gear tooth wear, housing integrity, and proper operation of the pressure relief mechanism․

Pressure relief valve details include spring rates, shim stack configurations, and setpoint adjustments․ Charts correlate shim thickness to relief pressure, enabling technicians to fine-tune oil pressure for optimal engine protection․ Torque specifications for pump mounting bolts and cover plates are clearly defined․ Proper function of the relief valve is paramount, preventing oil starvation or excessive pressure, and the manual stresses adherence to Lycoming’s recommended procedures for inspection and overhaul․

Magneto and Ignition Wiring

The Lycoming IO-320 parts manual provides comprehensive diagrams and parts lists for the magneto and ignition wiring systems․ It details each component, from the magnetos themselves – including impulse couplings, rotors, and breaker points – to the spark plugs, ignition switches, and associated wiring harnesses․ Precise wiring schematics illustrate correct connections, color codes, and grounding points, crucial for reliable ignition performance․

The manual specifies wire gauge requirements, connector types, and terminal crimping procedures․ It also covers magneto timing adjustments and troubleshooting common ignition faults․ Detailed breakdowns of magneto internal parts allow for precise component-level repairs․ Emphasis is placed on using Lycoming-approved replacement parts to ensure compatibility and maintain engine certification․ Proper installation and maintenance of the ignition system are vital for engine safety and performance, and the manual serves as a critical resource for technicians․

Starter and Generator Components

The Lycoming IO-320 parts manual meticulously details the starter and generator systems, essential for engine starting and electrical power․ It provides exploded views of the starter motor, including the drive pinion, solenoid, and armature assembly, alongside a complete parts list with Lycoming part numbers․ Similarly, the generator (or alternator, depending on the specific IO-320 variant) is thoroughly documented, showcasing components like the rotor, stator, voltage regulator, and rectifier․

Wiring diagrams illustrate the connection of these components to the aircraft’s electrical bus․ The manual specifies torque values for mounting bolts and provides guidance on troubleshooting common issues like slow cranking or insufficient charging․ It emphasizes the importance of using correct replacement parts to maintain system integrity and prevent electrical failures․ Detailed specifications for brushes, bearings, and other wear items are included, ensuring proper maintenance and longevity of these critical engine systems․

Overhaul and Replacement Parts

This section lists essential overhaul parts, including cylinder power assemblies (like SL36006W-A20P), and commonly replaced items for the IO-320 engine․

It details narrow and wide deck cylinder flange differences, aiding in accurate parts selection during engine maintenance and rebuilds․

Lycoming At Overhaul Parts Replacement List (O-320/IO-320)

The Lycoming At Overhaul Parts Replacement List, specifically for O-320 and IO-320 series engines, is a critical resource for technicians and owners undertaking engine rebuilds․ This list details components recommended for replacement during a comprehensive overhaul, ensuring optimal performance and reliability․ It encompasses a wide range of parts, from critical engine internals to essential accessories․

For example, the list includes details for the O-320-A2D and E Series engines․ Availability of these parts can vary, with some items, like Certified Lycoming O-320 Narrow Deck E2A Spot Faced Flange Crankcases, readily available with delivery times of 5-6 weeks․ The catalog references kits like the Millennium Cylinder Power Assembly Kit (SL36006W-A20P), compatible with multiple engine models including O-360, AEIO-360, and HIO-360 series․

Understanding this list is paramount for cost-effective and accurate engine restoration, guaranteeing adherence to Lycoming’s stringent quality standards․

Commonly Replaced Parts

During a Lycoming IO-320 engine overhaul, certain parts exhibit higher failure rates or are subject to mandatory replacement per service bulletins․ These commonly replaced components are crucial for restoring engine reliability and preventing future issues․ Key items include piston rings, connecting rod bearings, and main bearings, all subject to wear and tear during operation․

Valve guides and valve seals are also frequently replaced to maintain compression and prevent oil leakage․ Additionally, the oil pump and pressure relief valve are often overhauled or replaced to ensure adequate lubrication․ Cylinder assemblies, particularly those showing signs of wear or damage, are often replaced using kits like the Superior Millennium Cylinder Power Assembly․

Careful consideration of these frequently replaced parts is essential for a successful and durable engine overhaul․

Cylinder Power Assembly Kits (SL36006W-A20P Example)

Superior Millennium Cylinder Power Assembly Kits, such as the SL36006W-A20P, offer a convenient and cost-effective solution for cylinder overhaul or replacement․ These kits typically include a new cylinder, piston, rings, wrist pin, and retaining rings, providing all essential components for a complete cylinder assembly․

The SL36006W-A20P kit is compatible with a range of Lycoming engines, including the O-360-A, C, F, G, AEIO-360-B, H, LO-360-A, HIO-360-B, HO-360-C, and IO-360-B, E, M․ Utilizing these kits simplifies the overhaul process and ensures compatibility between components․

Proper installation and adherence to Lycoming’s service instructions are crucial for optimal performance and longevity․ These kits represent a significant value for engine rebuilders seeking quality and convenience․

Narrow Deck vs․ Wide Deck Cylinder Flanges

Lycoming IO-320 engines utilize either narrow deck or wide deck cylinder flanges, a critical distinction during parts replacement and overhaul․ Narrow deck engines generally precede wide deck designs, impacting cylinder compatibility and case selection․

Wide deck cylinder flanges are found on IO-320-B1A, -B1C, -C1A, -D1A, -D1B, -E1A, -E1B, -E2A, and -EB models, as well as AIO-320-B1B, -C1B, LIO-320-B1A, -C1A, and AEIO-320-D1B, -E1A, -E1B, -E2B engines․ This wider flange provides increased structural rigidity and improved cooling characteristics․

Using the incorrect flange type can lead to improper sealing, coolant leaks, and potential engine failure․ Careful identification of the engine model and corresponding flange type is paramount during parts ordering and installation, ensuring a reliable and safe operation․

Manual & Catalog Information

PC-303 is the key illustrated parts catalog for Lycoming IO-320 series engines,

covering AIO, LIO, and AEIO models, with detailed listings and model-specific variations․

PC-303 Parts Catalog Details

The PC-303 parts catalog serves as the definitive resource for identifying and sourcing components for the Lycoming IO-320 engine family, extending coverage to AIO-320, LIO-320, and AEIO-320 variants․ This comprehensive catalog meticulously details each part, providing crucial specifications and illustrations to ensure accurate identification and ordering․ It’s an invaluable tool for aircraft mechanics, owners, and parts suppliers alike․

PC-303 isn’t merely a listing; it’s an illustrated guide, visually representing each component for clarity․ It encompasses a wide range of engine series, including those with two-stroke designs (GP series)․ The catalog’s organization facilitates efficient navigation, allowing users to quickly locate parts based on engine model and component type․ Furthermore, it supports various model iterations, such as the IO-320 -B1A, -E2A, and others, ensuring compatibility and accuracy․ Utilizing PC-303 minimizes errors and streamlines the parts procurement process․

Illustrated Parts Catalog Usage

Effectively utilizing the Lycoming PC-303 illustrated parts catalog requires understanding its organizational structure․ Begin by identifying your specific engine model – for example, IO-320-B1A or LIO-320-C1A – as variations significantly impact part numbers․ The catalog is segmented by engine system, such as cylinders, pistons, or the ignition system, allowing targeted searches․ Illustrations accompany each part listing, aiding visual confirmation and reducing ordering errors․

Pay close attention to revision dates, as parts may be superseded or updated․ Cross-reference part numbers with your engine’s documentation to ensure compatibility․ The catalog’s index provides a quick lookup by part number․ When sourcing replacement parts, especially during overhauls, referencing PC-303 is crucial for maintaining airworthiness and adhering to Lycoming’s specifications․ Proper catalog usage guarantees accurate parts identification and contributes to safe and reliable aircraft operation․

Engine Series Coverage (IO-320, AIO-320, LIO-320, AEIO-320)

The Lycoming PC-303 parts manual provides comprehensive coverage for a range of four-cylinder engine series․ This includes the fuel-injected IO-320, the air-injected AIO-320, the horizontally opposed LIO-320, and the fuel-injected AEIO-320 variants․ Within each series, numerous model designations are supported, such as IO-320-B1A, -C1A, -D1A, -E1A, and -E2A, ensuring broad applicability․

The catalog details parts applicable to both narrow and wide deck cylinder flange configurations․ It’s vital to confirm your engine’s specific model when ordering, as even minor variations can necessitate different components․ The manual’s scope extends to encompass parts for overhauls, routine maintenance, and repairs across these engine families, offering a centralized resource for Lycoming engine support․ Accurate identification of the engine series is paramount for correct parts selection․

Specific Model Variations (-B1A, -E2A, etc․)

The Lycoming IO-320 parts manual, PC-303, meticulously details variations within each engine series․ Numerous model designations, like IO-320-B1A, -B1C, -C1A, -D1A, -D1B, -E1A, -E1B, -E2A, and -EB, each possess unique component specifications․ Similarly, AIO-320 models include -B1B and -C1B, while LIO-320 covers -B1A and -C1A․ AEIO-320 variations are also extensively documented, including -D1B, -E1A, -E1B, and -E2B․

These distinctions often relate to flange types (narrow vs․ wide deck) and specific manufacturing updates․ Correctly identifying your engine’s precise model is crucial for ordering the appropriate parts․ The manual provides detailed illustrations and part numbers tailored to each variation, minimizing the risk of incompatibility․ Always cross-reference your engine’s data plate with the catalog to ensure accurate parts selection and a successful maintenance outcome․