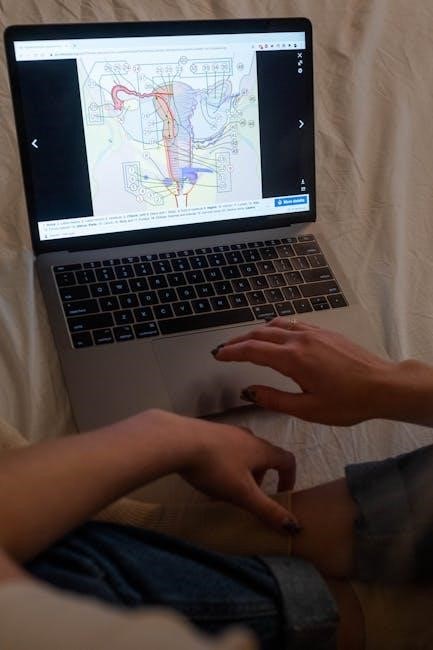

AC contactor wiring diagrams provide essential guidance for installing and understanding AC systems․ These diagrams detail connections, components, and control circuits, ensuring safe and efficient system operation․ They are crucial for HVAC and industrial applications, offering step-by-step instructions for technicians and engineers․ By following these diagrams, professionals can ensure proper wiring, reduce errors, and maintain system reliability․ These resources are indispensable for troubleshooting and maintaining AC contactors in various configurations, including 230V AC and 24V DC setups․ Always refer to certified PDF guides for accurate and up-to-date information․

Overview of AC Contactors

AC contactors are essential electrical components used to control and switch AC power circuits․ They are widely used in HVAC systems, industrial automation, and motor control applications․ These devices consist of a coil, contacts, and a housing, enabling them to handle high current flow while providing reliable on/off switching․ AC contactors are designed for frequent operation, making them ideal for systems requiring precise control․ They are available in various types, including AC-3, AC-3e, AC-7b, and AC-23, each suited for specific operational demands․ Their durability and flexibility ensure efficient performance in diverse electrical systems․

Importance of Wiring Diagrams in AC Systems

Wiring diagrams are crucial for the safe and efficient installation of AC systems․ They provide a clear visual representation of connections, ensuring correct setup and minimizing errors․ These diagrams help technicians identify components, such as contactors, coils, and switches, and understand their interactions․ Proper wiring reduces risks of short circuits and electrical hazards․ Diagrams also aid in troubleshooting, allowing quick identification of faults․ For HVAC and industrial applications, accurate wiring diagrams ensure system reliability and compliance with safety standards, making them an indispensable tool for professionals working with AC contactors and control circuits․

Understanding AC Contactor Components

AC contactors consist of key components like coils, contacts, and housing, which work together to control electrical circuits․ Coils generate magnetic fields to actuate contacts, enabling power distribution․ Housing protects internal parts from environmental factors․ These components ensure reliable operation in HVAC and industrial systems, making them essential for efficient control of electrical currents․ Proper understanding of these parts is vital for safe and effective wiring․

Structure and Function of AC Contactors

AC contactors are electromechanical devices with a robust structure designed to handle high electrical currents․ Their primary function is to connect and disconnect power supply lines in AC circuits․ The device comprises a coil, movable and fixed contacts, and a spring mechanism․ When the coil is energized, it generates a magnetic field, pulling the movable contact to meet the fixed contact and complete the circuit․ This operation is crucial for controlling motors and HVAC systems efficiently․ The contactor’s housing ensures durability and protection against environmental factors, ensuring reliable performance in various applications․

Key Components: Coils, Contacts, and Housing

AC contactors consist of three main components: the coil, contacts, and housing․ The coil acts as an electromagnet, generating a magnetic field to move the contacts․ The contacts (movable and fixed) facilitate the flow of electrical current when connected․ The housing provides structural support and protection against environmental factors․ Together, these components ensure reliable switching and control of AC circuits․ Proper wiring of these elements is essential for safe and efficient operation, as detailed in wiring diagrams for AC contactors․

Types of AC Contactors

AC-3, AC-3e, AC-7b, and AC-23 Contactors

AC-3, AC-3e, AC-7b, and AC-23 contactors are specialized for different applications․ AC-3 and AC-3e are commonly used in HVAC systems for controlling compressors and fan motors․ AC-7b contactors handle high-current applications, while AC-23 models are designed for low-voltage control circuits․ These contactors are rated for specific operational currents and voltages, ensuring compatibility with diverse AC systems․ Their wiring diagrams provide clear guidance for installation and maintenance, making them essential for technicians working with HVAC and industrial automation systems․ Proper selection and wiring of these contactors are crucial for safe and efficient system operation․

AC-3 and AC-3e contactors are designed for HVAC systems, controlling compressors and fan motors․ AC-7b contactors handle high-current applications, while AC-23 models are suited for low-voltage control circuits․ These contactors are rated for specific operational currents and voltages, ensuring compatibility with diverse AC systems․ Their wiring diagrams provide clear installation guidance, essential for technicians․ Proper selection and wiring are crucial for safe and efficient operation, making these contactors indispensable in industrial automation and HVAC applications․ Always refer to certified PDF guides for accurate specifications and wiring instructions․

Specialized Contactors for HVAC Systems

Specialized AC contactors are designed for HVAC systems, enabling efficient control of compressors and fan motors․ These contactors are tailored for high switching frequencies and harsh environmental conditions․ They support 230V AC control circuits, ensuring reliable operation in heating and cooling applications․ Models like the NXC series are specifically engineered for HVAC, offering robust performance and long service life․ Their wiring diagrams provide detailed connections for low-voltage controls, making installation straightforward․ These contactors are essential for maintaining optimal HVAC system performance, ensuring energy efficiency and reliability in residential and commercial settings․ Always consult certified diagrams for precise wiring guidance․

Reading and Interpreting AC Contactor Wiring Diagrams

Understanding AC contactor wiring diagrams is crucial for safe and efficient system installation․ These diagrams use standardized symbols to represent components, ensuring clarity and precision in wiring processes․ By interpreting these diagrams accurately, technicians can identify connections, control circuits, and safety features․ Proper interpretation prevents errors and ensures compliance with electrical standards, making it essential for both novice and experienced professionals working with AC systems․

Symbols and Notations Used in Diagrams

AC contactor wiring diagrams use standardized symbols to represent components, ensuring clarity and consistency․ Common symbols include coils, contacts, and control circuits, each with distinct notations․ Lines represent wires, while rectangles or circles denote contactors․ Arrows indicate current flow, and dashed lines show connections․ These symbols are universally recognized, simplifying diagram interpretation․ Proper understanding of these notations is essential for accurate wiring and troubleshooting․ They ensure compliance with electrical standards, preventing errors and enhancing safety․ Always refer to the legend or key provided for precise identification and interpretation of symbols in the diagram․

Common Configurations for AC Control Circuits

AC control circuits often use exclusive or non-exclusive wiring configurations․ Exclusive setups isolate control functions, while non-exclusive allow shared control signals․ Diagrams frequently depict 230V AC and 24V DC systems, with distinct wiring for safety․ These configurations ensure proper operation of contactors, relays, and sensors․ Exclusive control is ideal for precise operations, whereas non-exclusive suits applications requiring multiple control points․ Always follow the recommended wiring layouts to maintain system reliability and safety․ Consulting a certified PDF guide ensures compliance with electrical standards and prevents potential hazards․

Safety Considerations for AC Contactor Wiring

Ensure all wiring meets safety standards to prevent electrical hazards․ Always disconnect power before working on circuits․ Use appropriate PPE and follow manufacturer guidelines strictly․ Regular inspections are crucial to identify potential faults and ensure compliance with safety protocols․ Proper grounding and insulation are essential to avoid shocks or short circuits․ Adhere to local electrical codes and best practices to maintain a safe working environment when handling AC contactors and their wiring systems․ Safety should never be compromised during installation or maintenance․ Always refer to certified diagrams and manuals for specific safety precautions․

Electrical Safety Precautions

When working with AC contactor wiring, always disconnect the power supply to avoid electric shocks or injuries․ Wear appropriate PPE, including insulated gloves and safety glasses․ Ensure proper grounding of all equipment to prevent voltage spikes․ Never touch live wires or components without verification of de-energization․ Use tools rated for the voltage and current levels involved․ Follow local electrical codes and manufacturer guidelines strictly․ Regularly inspect wiring and connections for wear or damage․ Keep emergency equipment nearby, such as fire extinguishers․ Always refer to certified diagrams and manuals for specific safety protocols․ Adhere to lockout/tagout procedures to ensure system safety during maintenance․

Best Practices for Handling AC Systems

Always follow manufacturer guidelines and certified diagrams for AC systems․ Ensure proper grounding to prevent voltage spikes and ensure safety․ Regularly inspect wiring and connections for wear or damage․ Use appropriate tools rated for the system’s voltage and current․ Follow local electrical codes and standards․ Handle frequent starts and stops carefully, adhering to rated operational capacities like AC-3 and AC-7b․ Keep the system clean and well-ventilated to prevent overheating․ Use surge protectors for sensitive components․ Adhere to lockout/tagout procedures during maintenance․ Refer to resources like RWMA bulletin 5․015 for specific configurations․ Properly test systems before and after modifications․

Installation Guide for AC Contactors

Mount the contactor securely, ensuring proper alignment․ Follow the wiring diagram for correct connections․ Tighten all terminals firmly․ Refer to technical specifications for voltage compatibility․ Ensure safe grounding․

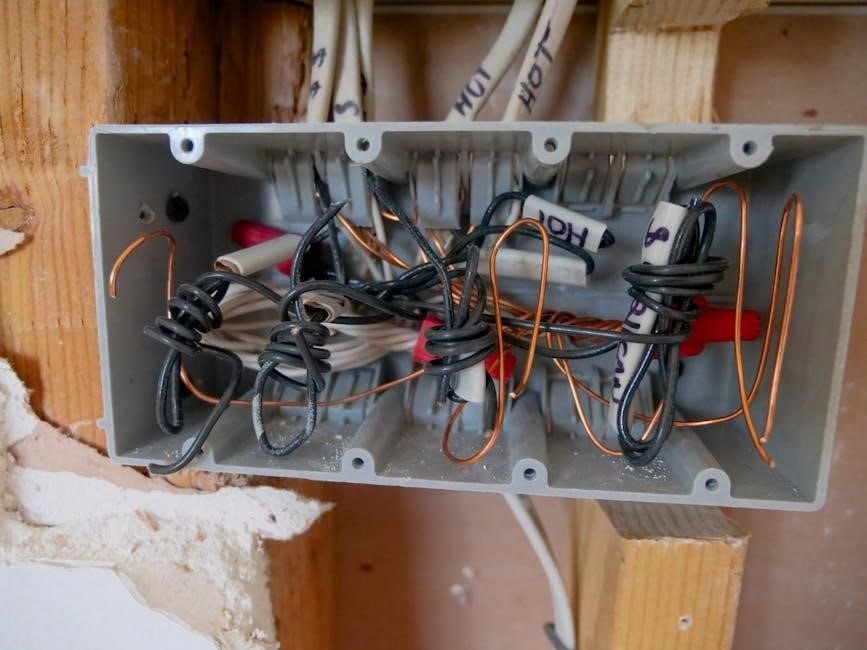

Step-by-Step Installation Process

Begin by mounting the AC contactor on a suitable surface, ensuring it is level and secure․

Identify the incoming power supply and connect it to the contactor’s input terminals․

Follow the wiring diagram to link the contactor to the motor or load․

Connect the control circuit, including any switches or sensors․

Double-check all connections for tightness and correctness․

Power up the system and test the contactor’s operation․

Ensure all safety measures are in place before finalizing the installation․

Mounting and Wiring Recommendations

Mount the AC contactor on a flat, clean surface, ensuring it is securely fastened to prevent vibration․

Use the recommended torque for terminal connections to avoid damage․

Wiring should be neatly organized, with wires of appropriate gauge for the load․

Ensure all connections are tight and follow the diagram for correct polarity․

Avoid overloading the contactor, and keep wires away from heat sources․

For outdoor installations, protect the contactor from direct sunlight and moisture․

Always refer to the PDF guide for specific mounting and wiring instructions tailored to your AC system․

Troubleshooting AC Contactor Issues

Troubleshooting AC contactor issues involves identifying common faults like coil failure or contact wear․ Use wiring diagrams to trace connections and test components systematically․ Always refer to the PDF guide for specific solutions and safety precautions to ensure efficient and safe repairs․

Common Faults and Their Solutions

Common AC contactor faults include shorted contacts, low voltage, or thermal lockouts․ Shorted contacts require immediate replacement to prevent system damage․ Low voltage issues can be resolved by checking the power supply and ensuring proper wiring connections․ Thermal lockouts often occur due to overheating, which may indicate faulty coils or excessive load․ Refer to the wiring diagram PDF for specific troubleshooting steps․ Regular inspection of contacts and coils can prevent these faults․ Always ensure proper wiring and load calculations to maintain optimal performance and safety․

Diagnosing Contactor Failures

Diagnosing AC contactor failures involves identifying signs like short circuits, power loss, or thermal overload․ Inspect for physical damage or burn marks on contacts and coils․ Use multimeters to check voltage levels and resistance․ Low voltage or open circuits may indicate faulty wiring․ Thermal overload could result from excessive current or poor ventilation․ Refer to the wiring diagram PDF for troubleshooting steps․ Regularly test contacts for wear and ensure proper alignment․ Addressing issues promptly prevents system downtime and enhances safety․ Always consult the manufacturer’s manual for specific diagnostic procedures․

Wiring Diagrams for Different AC Systems

Wiring diagrams vary for AC systems, covering exclusive and non-exclusive controls․ Exclusive setups use 230V AC or 24V DC, while non-exclusive systems combine both voltages․ These diagrams ensure proper connections․

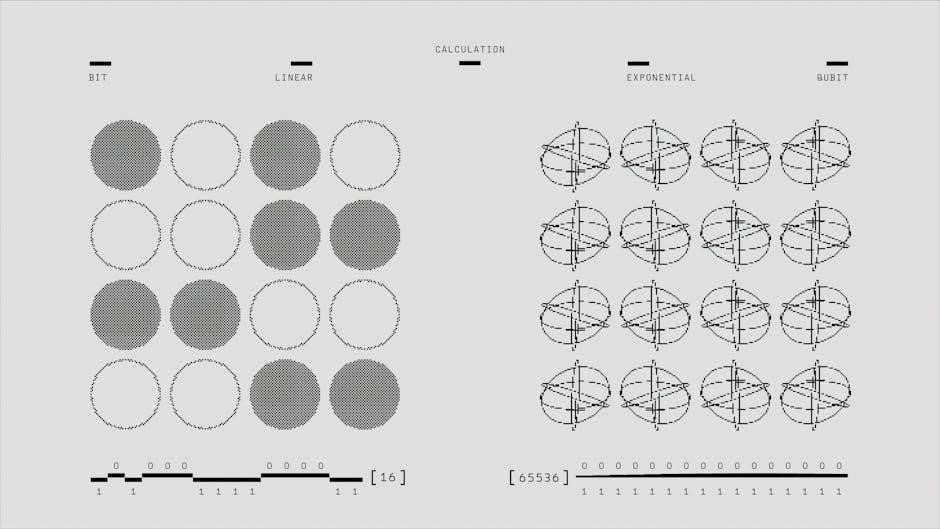

Exclusive vs․ Non-Exclusive Control Wiring

Exclusive control wiring uses either 230V AC or 24V DC, while non-exclusive systems combine both voltages․ Exclusive setups are simpler, using a single voltage for control, while non-exclusive systems offer flexibility by supporting dual voltage inputs․ Exclusive wiring is ideal for dedicated AC systems, whereas non-exclusive configurations are better for mixed or variable voltage applications․ Both setups require careful wiring to ensure compatibility and safety, as detailed in RWMA bulletin 5․015․ Proper mounting and wiring recommendations must be followed to avoid operational issues and ensure reliable performance․

230V AC and 24V DC Control Configurations

230V AC systems are commonly used for high-power applications, controlling compressors and HVAC units, while 24V DC systems are preferred for safety and low-voltage control circuits․ Wiring diagrams often show exclusive or non-exclusive setups, allowing either 230V AC (Y1 0) or 24V DC (Y1 1) configurations․ These setups ensure compatibility with different control boards and contactors․ Proper wiring is crucial to prevent short circuits and ensure efficient operation․ Always refer to certified PDF guides for accurate installations and troubleshooting in both AC and DC control environments․

Technical Specifications for AC Contactors

AC contactors operate at 230V AC or 24V DC, with frequencies up to 60 Hz․ They feature PLC interfaces for smart control and compatibility with HVAC systems․

Rated Operational Current and Voltage

AC contactors are designed to handle specific operational current and voltage ratings, ensuring safe and efficient performance․ Typical ratings include 230V AC or 24V DC, with frequencies up to 60 Hz․ The operational current capacity varies based on the contactor type, such as AC-3 or AC-7b, and is crucial for motor control and HVAC systems․ These ratings ensure compatibility with various electrical systems, preventing overheating or short circuits․ Always verify the manufacturer’s specifications to match the contactor’s ratings with the system requirements for optimal functionality and safety․

Compatibility with HVAC and Heat Pump Systems

AC contactors are integral to HVAC and heat pump systems, controlling power supply to compressors and fans․ They ensure efficient operation by managing high current loads safely․ Modern contactors often feature built-in PLC interfaces, enabling smart control and seamless integration with advanced HVAC systems․ Compatibility with both 230V AC and 24V DC configurations allows versatile application across various heating and cooling setups․ Proper installation, as per wiring diagrams, ensures reliable performance and energy efficiency in HVAC systems, making AC contactors indispensable for modern climate control solutions․

Advanced Features of Modern AC Contactors

Modern AC contactors integrate PLC interfaces for smart control, enabling high-voltage AC/DC operations and remote monitoring․ They enhance efficiency and adaptability in industrial and HVAC applications․

PLC Interface and Smart Control Features

Modern AC contactors feature built-in PLC interfaces, enabling seamless integration with smart control systems․ These interfaces support high-voltage AC/DC operations, ranging from 100 to 250 V AC/DC or 250 to 500 V AC/DC․ They allow for advanced automation, remote monitoring, and precise control of motor and HVAC systems․ This functionality enhances operational efficiency, reduces downtime, and provides real-time data for system optimization․ The PLC interface also supports various control configurations, making it adaptable to different industrial and commercial applications․

High-Voltage AC/DC Coil Operations

High-voltage AC/DC coil operations in AC contactors are designed for versatile applications, supporting voltages from 100 to 250 V AC/DC and up to 500 V AC/DC․ These coils ensure reliable switching in demanding environments, offering consistent performance across a wide voltage range․ They are suitable for both high-power industrial automation and precise HVAC control systems․ The robust design of these coils minimizes voltage fluctuations, ensuring stable operation and longevity․ This capability makes them ideal for advanced automation systems requiring high reliability and adaptability․

Applications of AC Contactors

AC contactors are essential for controlling high-power devices in HVAC systems, industrial automation, and motor control, ensuring efficient and reliable operation․

Use in Air Conditioning and Heating Systems

AC contactors are crucial in air conditioning and heating systems, controlling the flow of electrical power to compressors and fan motors․ They ensure reliable operation by switching high-current circuits safely․ In HVAC systems, contactors act as the primary power control devices, enabling seamless start/stop functions․ Their durability and efficiency make them indispensable for managing heavy loads in heating and cooling applications․ Proper wiring, as detailed in diagrams, ensures optimal performance and prevents system failures․ This makes them essential for maintaining consistent indoor air quality and temperature regulation in residential and commercial settings․

Industrial Automation and Motor Control

AC contactors are integral to industrial automation, enabling precise motor control in manufacturing processes․ They efficiently manage high-power circuits, ensuring smooth start/stop operations and protecting equipment from voltage spikes․ In automation, contactors are used to control motors, pumps, and conveyor systems, enhancing productivity and safety․ Their reliability in harsh environments makes them ideal for industrial applications․ Wiring diagrams provide clear instructions for integrating contactors into motor control panels, ensuring seamless system integration and minimizing downtime․ This contributes to overall industrial efficiency and operational consistency․

Maintenance and Upkeep of AC Contactors

Regular maintenance ensures AC contactors operate efficiently and reliably․ Clean contacts, inspect wiring, and check for wear․ Replace faulty components promptly to prevent system failures․ Schedule routine inspections and follow manufacturer guidelines for optimal performance and longevity․

Cleaning and Replacing Contacts

Regular cleaning of AC contactor contacts is essential to ensure reliable operation․ Turn off the power before cleaning to avoid electrical hazards․ Use a soft, dry cloth or silica-based contact cleaner to remove dirt and oxidation․ Replace contacts if they show significant wear or pitting․ Refer to the wiring diagram for proper disassembly instructions․ Always follow manufacturer guidelines for replacement parts and cleaning materials․ Proper maintenance extends the lifespan of the contactor and prevents system malfunctions․ Use professional tools to avoid damaging the contacts or surrounding components during the process․

Regular Inspection and Testing

Regular inspection of AC contactors ensures optimal performance and safety․ Check for signs of wear, overheating, or arcing on contacts and coils․ Verify that all connections are secure and free from corrosion․ Use a multimeter to test coil resistance and ensure proper voltage levels․ Refer to the wiring diagram for correct test points and procedures․ Perform these inspections during scheduled maintenance to prevent unexpected failures․ Testing helps identify potential issues before they escalate, ensuring reliable operation of the AC system and extending the lifespan of the contactor․

Resources for AC Contactor Wiring Diagrams

Downloadable PDF guides and manuals provide detailed wiring diagrams for AC contactors․ Online tools and tutorials offer step-by-step instructions and interactive diagrams for various AC systems․

Downloadable PDF Guides and Manuals

Extensive PDF guides and manuals are available for AC contactor wiring diagrams․ These documents provide detailed schematics, installation instructions, and technical specifications․ They cover various AC contactor types, including AC-3, AC-3e, and AC-7b, ensuring compatibility with HVAC and industrial systems․ The manuals often include troubleshooting tips and safety precautions, making them invaluable for professionals․ Access these resources online for precise wiring configurations and to maintain system efficiency and safety․

Online Tools and Tutorials

Online tools and tutorials offer comprehensive guidance for understanding AC contactor wiring diagrams․ These resources include interactive guides, video tutorials, and step-by-step webinars․ They provide detailed explanations of circuit connections, control configurations, and troubleshooting methods․ Many platforms offer downloadable PDFs and real-time simulations to practice wiring techniques․ These tools are invaluable for professionals and DIY enthusiasts alike, ensuring accurate and safe installations․ Regular updates keep the content aligned with the latest industry standards and advancements in AC contactor technology․

AC contactor wiring diagrams are an essential resource for safe and efficient system installations․ They ensure proper connections, reducing errors and enhancing reliability․ Always refer to certified guides for accuracy․

AC contactor wiring diagrams are crucial for understanding and installing AC systems, detailing connections, components, and control circuits․ They are essential for HVAC and industrial applications, offering step-by-step guidance for technicians․ Key points include proper wiring techniques, safety precautions, and troubleshooting common faults․ Diagrams cover configurations like exclusive and non-exclusive controls, 230V AC, and 24V DC setups․ Technical specifications, such as rated current and voltage, ensure compatibility with systems․ Regular inspections and maintenance, like cleaning contacts, are vital for reliability․ These resources provide comprehensive guidance for working with AC contactors efficiently and safely․

Final Tips for Working with AC Contactors

Always refer to the wiring diagram and manufacturer’s guidelines for specific configurations․ Use appropriate tools to handle high-voltage components safely․ Verify coil voltage compatibility with control circuits before installation․ Regularly inspect and clean contacts to maintain optimal performance․ Ensure proper grounding to prevent electrical hazards․ For advanced setups, consider PLC interfaces for smart control․ Follow recommended mounting and wiring practices to avoid overheating․ Stay updated with the latest technical specifications and best practices for AC contactors․ By adhering to these tips, you can ensure efficient and reliable operation of your AC systems․